Tire technology evolves at a rate that mimics the world around us. The constant fluctuations in fuel prices affect everything from material costs to transportation fees and, clearly, the end product.

In order to help ease the overall burden on the end user (read: you and I), tire companies “green” their tire technologies in the hopes of saving us some money at the pumps.

Hankook, a South Korean tire manufacturer and one of the largest, is working on alternatives and technologies to help the cause, as are most other tire makers.

Hankook is a lesser-known producer but, like everything else from Korea, they are rapidly growing. Their wide-ranging presence -- from motorsports to original equipment on a number of cars -- explains why they were chosen for this series of questions pertaining to green tire technology.

Q: Low rolling-resistance tires are clearly a current trend. Hankook’s enfren tire is one such tire that promises huge improvements on numerous levels over a regular tire. Can you explain some of the principal improvements?

A: First and foremost, it is important to understand the causes of rolling resistance in tires. The primary cause is deformation. During the rolling motion on a surface, tires continuously deform and then recover, leading to an increase in heat and a loss of energy. This loss of energy ties directly into the resistance the tire experiences. How much a tire deforms is closely related to the load it carries (affected by the vehicle weight and gravity), air pressure, design and structure, surface type and speed.

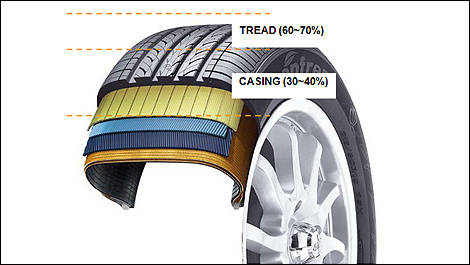

Second; different parts of a tire contribute differently to rolling resistance. In general, the tread portion of a tire can account for 50-60% of rolling resistance, while the casing portion underneath the tread can contribute 40-50%.

Hankook Tire’s lower rolling resistance tire design focuses on creating less tire deformation combined with optimized volume control. With a design that includes a lowered tread part deformation, an even tread contact shape and contact pressure, sidewall stiffness control, and optimized tread volume, the components come together to provide consumers with a tire that offers lower than average rolling resistance.

Q: Can you elaborate further on how enfren can minimize the loss of energy from its structural design technology?

A: The fundamental structural design of the enfren is our SCCT (Secure Control Contour Theory) Profile. This profile design betters the tires handling with increased tension of the carcass, while simultaneously enhancing the tires durability by minimizing deformation under continuous pressure. In addition, the SCCT profile leads to a more uniform pressure for improved ground contact.

The technology involved in the tire compound is also important. By combining new materials and a new mixing technology, that disperses reinforcement additives like silica, Hankook has developed the Fuel Saving compound technology, which improves fuel efficiency along with wet braking performance.

How the tire compound is mixed is the third element involved in the structural design technology that allows the enfren to minimize loss of energy. Hankook’s Intelligent Mixing Control System controls the processes from material input to mixing.

In order to implement a superior and uniform performance with the rubber, silica and additives, the Mixer is controlled to be operated at optimal temperature, ram pressure, electric current, and voltage conditions. Hankook’s Intermeshing Rotor disperses silica evenly for a good reaction between the rubber and silica. The result is a uniform distribution which improves wear resistance and fuel efficiency.

Q: How far can the technology behind low rolling resistance tires be taken, and does Hankook intend to apply it to different lines of tires?

A: The fundamental low rolling resistance technology is being applied to virtually every tire designed for passenger vehicles -- from Original Equipment to Replacement Tires. In general, it’s not difficult for a leading tire manufacturer, such as Hankook, to build a lower rolling resistance tire. However, such tires may not be able to satisfy other needs such as braking, acceleration and comfort when deeply specialized in lower rolling resistance.

Hankook conducts careful research to ensure that tires are optimized for consumer needs, while also incorporating the highest percentage of lower rolling resistance possible. For instance, take the Hankook Optimo H426, a general touring tire for sedans. It offers the functions required by consumers while featuring 20% lower rolling resistance compared to the previous generation.

In order to help ease the overall burden on the end user (read: you and I), tire companies “green” their tire technologies in the hopes of saving us some money at the pumps.

Hankook, a South Korean tire manufacturer and one of the largest, is working on alternatives and technologies to help the cause, as are most other tire makers.

Hankook is a lesser-known producer but, like everything else from Korea, they are rapidly growing. Their wide-ranging presence -- from motorsports to original equipment on a number of cars -- explains why they were chosen for this series of questions pertaining to green tire technology.

Q: Low rolling-resistance tires are clearly a current trend. Hankook’s enfren tire is one such tire that promises huge improvements on numerous levels over a regular tire. Can you explain some of the principal improvements?

A: First and foremost, it is important to understand the causes of rolling resistance in tires. The primary cause is deformation. During the rolling motion on a surface, tires continuously deform and then recover, leading to an increase in heat and a loss of energy. This loss of energy ties directly into the resistance the tire experiences. How much a tire deforms is closely related to the load it carries (affected by the vehicle weight and gravity), air pressure, design and structure, surface type and speed.

Second; different parts of a tire contribute differently to rolling resistance. In general, the tread portion of a tire can account for 50-60% of rolling resistance, while the casing portion underneath the tread can contribute 40-50%.

Hankook Tire’s lower rolling resistance tire design focuses on creating less tire deformation combined with optimized volume control. With a design that includes a lowered tread part deformation, an even tread contact shape and contact pressure, sidewall stiffness control, and optimized tread volume, the components come together to provide consumers with a tire that offers lower than average rolling resistance.

|

| Photo: Hankook |

Q: Can you elaborate further on how enfren can minimize the loss of energy from its structural design technology?

A: The fundamental structural design of the enfren is our SCCT (Secure Control Contour Theory) Profile. This profile design betters the tires handling with increased tension of the carcass, while simultaneously enhancing the tires durability by minimizing deformation under continuous pressure. In addition, the SCCT profile leads to a more uniform pressure for improved ground contact.

The technology involved in the tire compound is also important. By combining new materials and a new mixing technology, that disperses reinforcement additives like silica, Hankook has developed the Fuel Saving compound technology, which improves fuel efficiency along with wet braking performance.

How the tire compound is mixed is the third element involved in the structural design technology that allows the enfren to minimize loss of energy. Hankook’s Intelligent Mixing Control System controls the processes from material input to mixing.

In order to implement a superior and uniform performance with the rubber, silica and additives, the Mixer is controlled to be operated at optimal temperature, ram pressure, electric current, and voltage conditions. Hankook’s Intermeshing Rotor disperses silica evenly for a good reaction between the rubber and silica. The result is a uniform distribution which improves wear resistance and fuel efficiency.

Q: How far can the technology behind low rolling resistance tires be taken, and does Hankook intend to apply it to different lines of tires?

A: The fundamental low rolling resistance technology is being applied to virtually every tire designed for passenger vehicles -- from Original Equipment to Replacement Tires. In general, it’s not difficult for a leading tire manufacturer, such as Hankook, to build a lower rolling resistance tire. However, such tires may not be able to satisfy other needs such as braking, acceleration and comfort when deeply specialized in lower rolling resistance.

Hankook conducts careful research to ensure that tires are optimized for consumer needs, while also incorporating the highest percentage of lower rolling resistance possible. For instance, take the Hankook Optimo H426, a general touring tire for sedans. It offers the functions required by consumers while featuring 20% lower rolling resistance compared to the previous generation.

|

| Hankook’s enfren tire (Photo: Hankook) |